Long Neck PCO Preforms

Long Neck PET Preforms Manufacturer

As a Long neck PET preforms manufacturer, Hawk Exim produces export-grade PET preforms designed for beverage and specialty bottle applications where neck precision and consistent performance are essential. Our manufacturing focus is on dimensional accuracy, stable blowing behavior, and dependable bulk supply for domestic and international bottling businesses.

Long neck bottles require tighter control during manufacturing, as even small variations can affect bottle formation and closure fit. We design our PET preforms to perform reliably in real production environments, not just on paper.

We focus on manufacturing reliability and repeatable quality, helping bottling businesses maintain efficient production without unnecessary downtime or material variation.

Key Features

As a long neck PET preforms manufacturer, we maintain direct control over production processes, tooling accuracy, and quality checks.

Smooth Neck Finish

Long Neck PCO preforms are produced with accurate thread profiles and a smooth neck finish, enabling perfect cap fitment and leak-proof sealing. This ensures stable performance during capping and prevents spillage during handling and transport.

Consistent Blowing Performance

The preforms are engineered for optimized material distribution, giving uniform wall thickness, strong base formation, and minimal blowing defects. This leads to high output and reduced wastage in blow molding machines.

High Strength & Durability

Manufactured using premium PET resin, these preforms offer excellent impact resistance and structural rigidity. They withstand compression, drops, and rough handling throughout the supply chain.

Superior Clarity & Finish

Each preform delivers crystal-clear transparency and a glossy surface, ensuring visually appealing, premium-quality bottles that elevate brand value.

International PCO Standard Compatibility

Designed to meet PCO 1810 standards, these preforms perfectly match global bottling line requirements, making them ideal for export markets and high-speed production lines.

Food-Grade & Safe for Beverages

Made from FDA-approved PET resin, they are odorless, non-toxic, and safe for packaging drinking water, carbonated beverages, juices, and flavored drinks.

Applications of Long Neck PET Preforms

Our long neck PET preforms are suitable for a range of packaging applications, including:

Packaged Drinking Water

Carbonated Soft Drinks (CSD)

Juices & Flavored Beverages

Energy & Sports Drinks

Export-Oriented Bottled Products

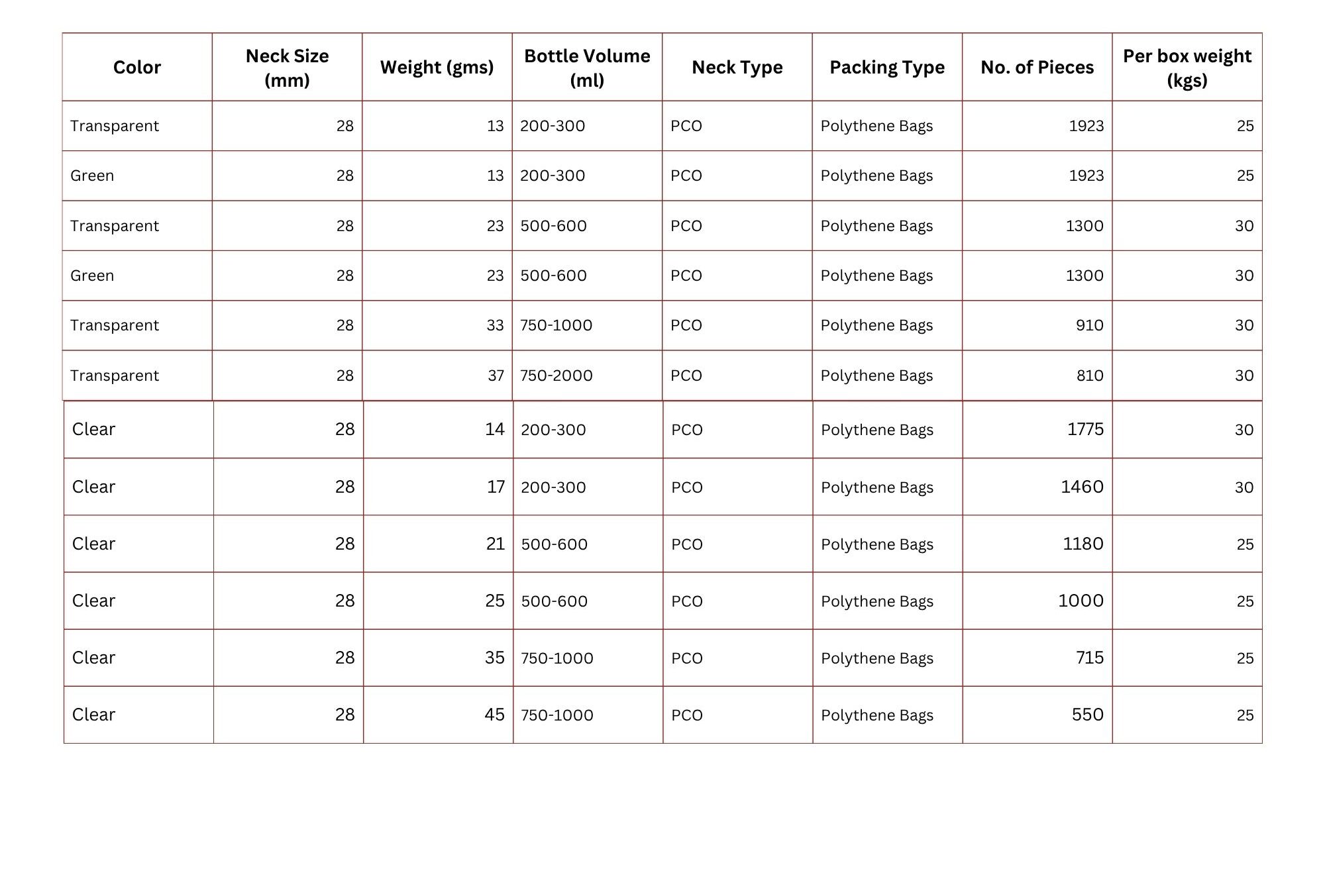

Long neck PCO preforms specifications

If you are looking for a dependable long neck PET preforms manufacturer with experience in beverage and specialty bottle packaging, Hawk Exim is ready to support your requirements.

Other Pages

Home

About

Services

Our Products

Contact Us

Quick Links

Privacy Policy

Term of Services

FAQ

Work Hours

- Mon-Sat 09:00 A.M -10:00 P.M (IST)

- Sun 09:00 A.M -02:00 P.M (IST)

Download Detailed Product Specifications

© 2025 Powered by Hawk Exim